An entire improvement platform for your mine. Not just another FMS

MaxMine is the only OEM agnostic platform to combine high resolution data, AI, machine learning and coaching to improve your mine’s safety, productivity and sustainability.

The Platform

A full-stack mining advantage. From data to action.

No more assumptions. No more blind spots. Just smarter decision-making, powered by the most advanced mining platform in the industry.

Idle Time Optimisation

Take back control of idle time and keep your fleet moving

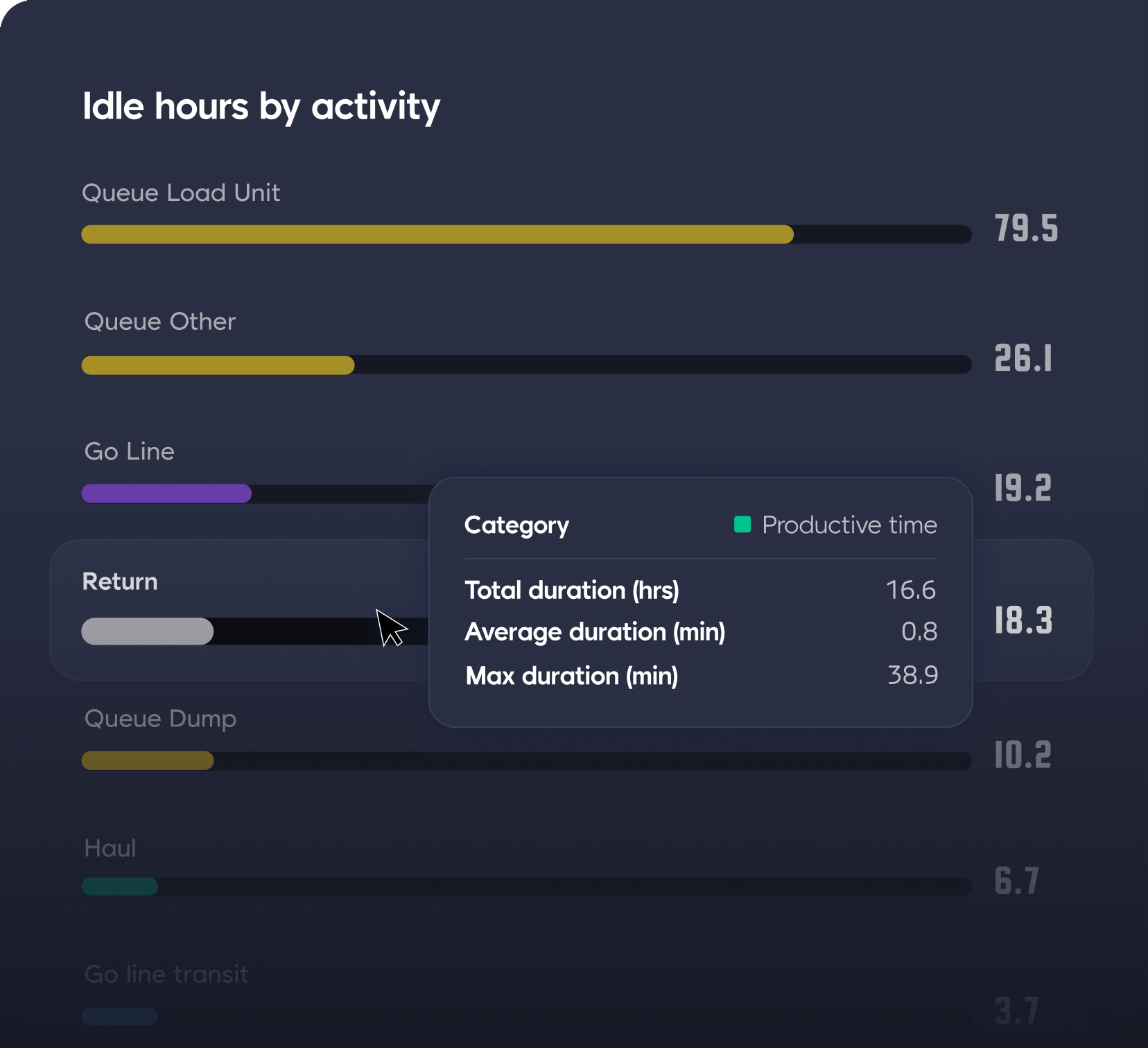

Visualise idle time and what’s causing it on your site for precise, targeted interventions that save you time, fuel and money.

Focus your attention on what matters most

Get a clear breakdown of idle across all equipment to help you focus energy where it will have the most impact

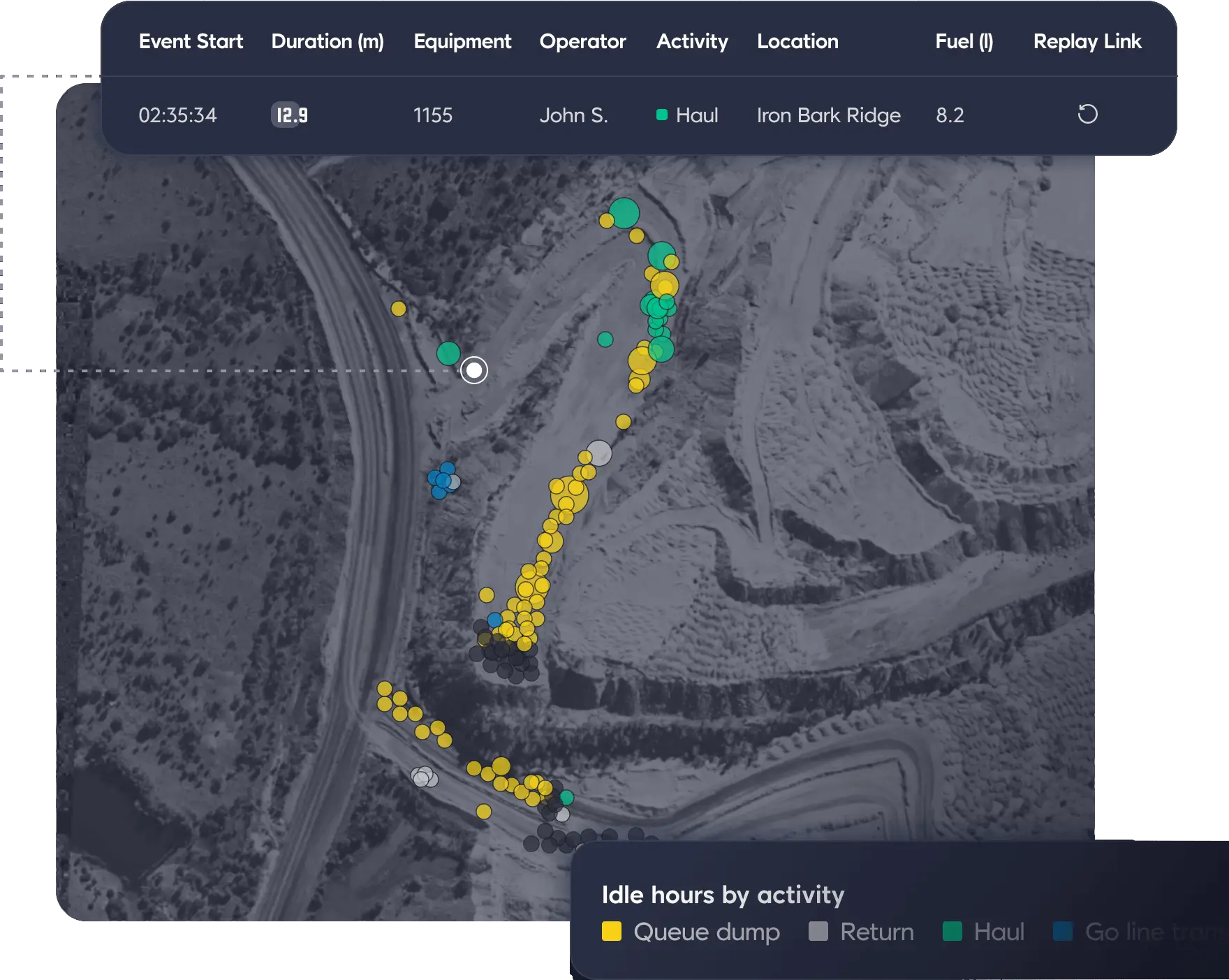

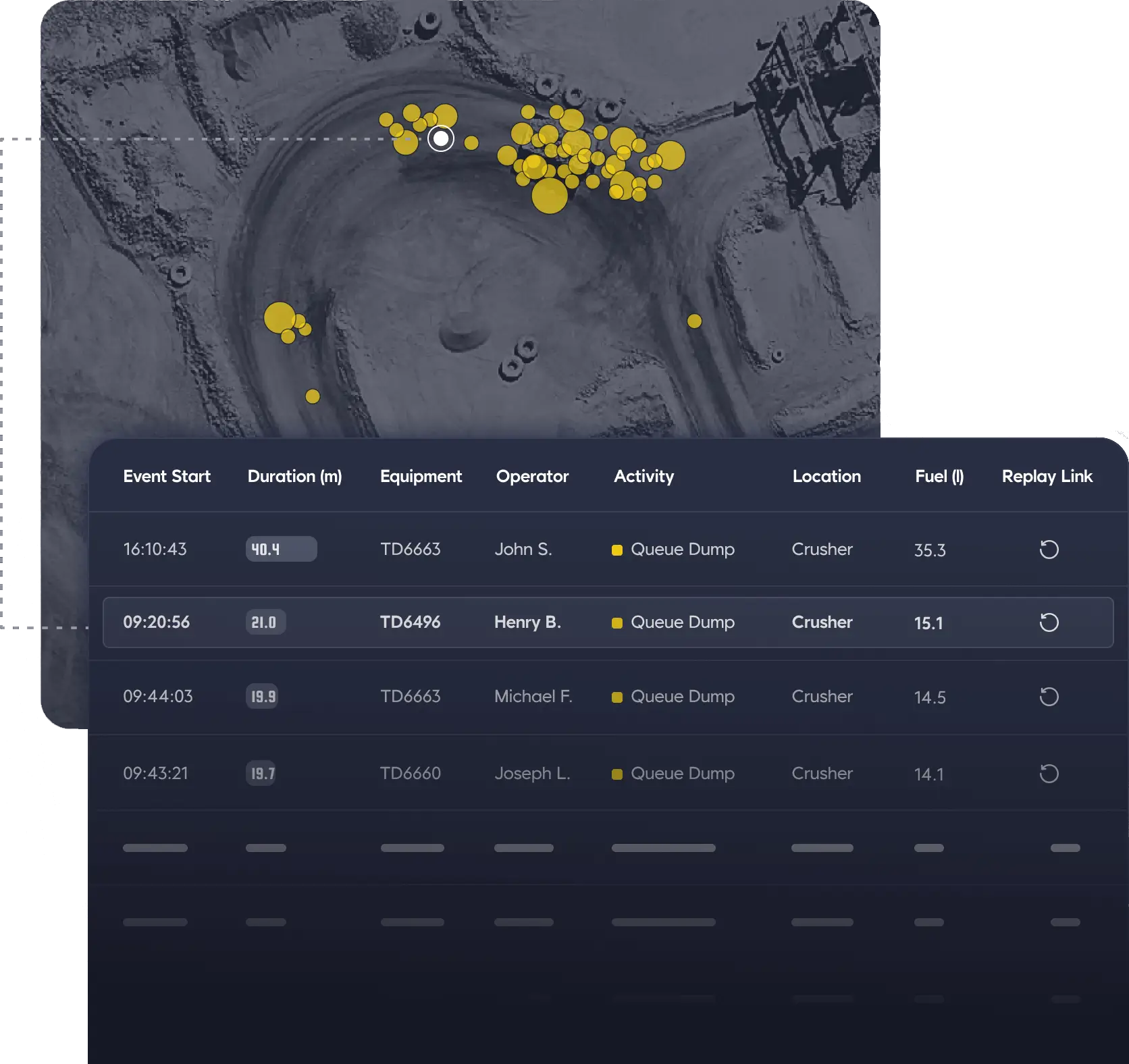

Idle time data you can trust and stand behind

With MaxMine, every idle event is logged and contextualised — by location, operator, and activity — so you can spot inefficiencies and eliminate wasted time with confidence.

No more excuses for long idle times

Anyone can replay an idle event to understand what caused the delay and pinpoint operators who regularly indulge in excessive idle and so that you can ask the right questions with confidence. No more excuses.

Unblock bottlenecks to get things moving

Spot operational bottlenecks like queuing hotspots, crusher performance, dump congestion, or single-lane roads to understand where inefficiencies are happening and keep things flowing.

See when you’re winning the battle

Trend analysis that shows where you’re making progress so you can sustainably minimise wasted machine hours.

Safer Operations

The world’s best Black Box Recorder for mining equipment

MaxMine connects operator behaviour, machine response, and real-world context — exposing the root causes behind every incident and driving the behaviour change needed for lasting safety improvement.

Your complete incident record

With millions of asset hours recorded, not a moment is missed – even in critical incidents. Our “always on” loggers with backup power ensure a complete, reliable record of what happened.

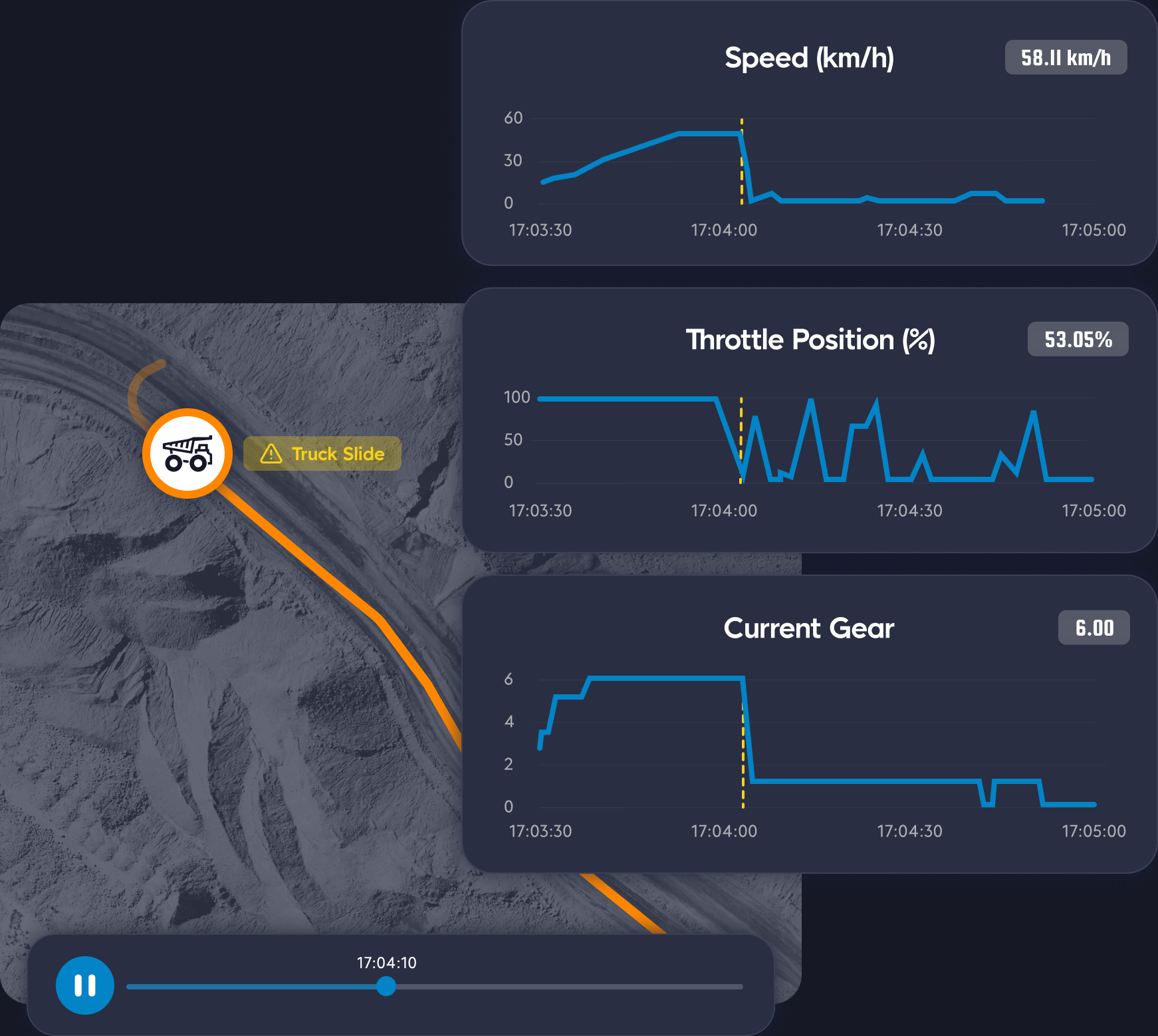

Reconstruct what really happened

Pause, rewind, and replay the movement of your fleet for a given shift, synchronised with rich operational context. Build a second by second picture of what happened in the field.

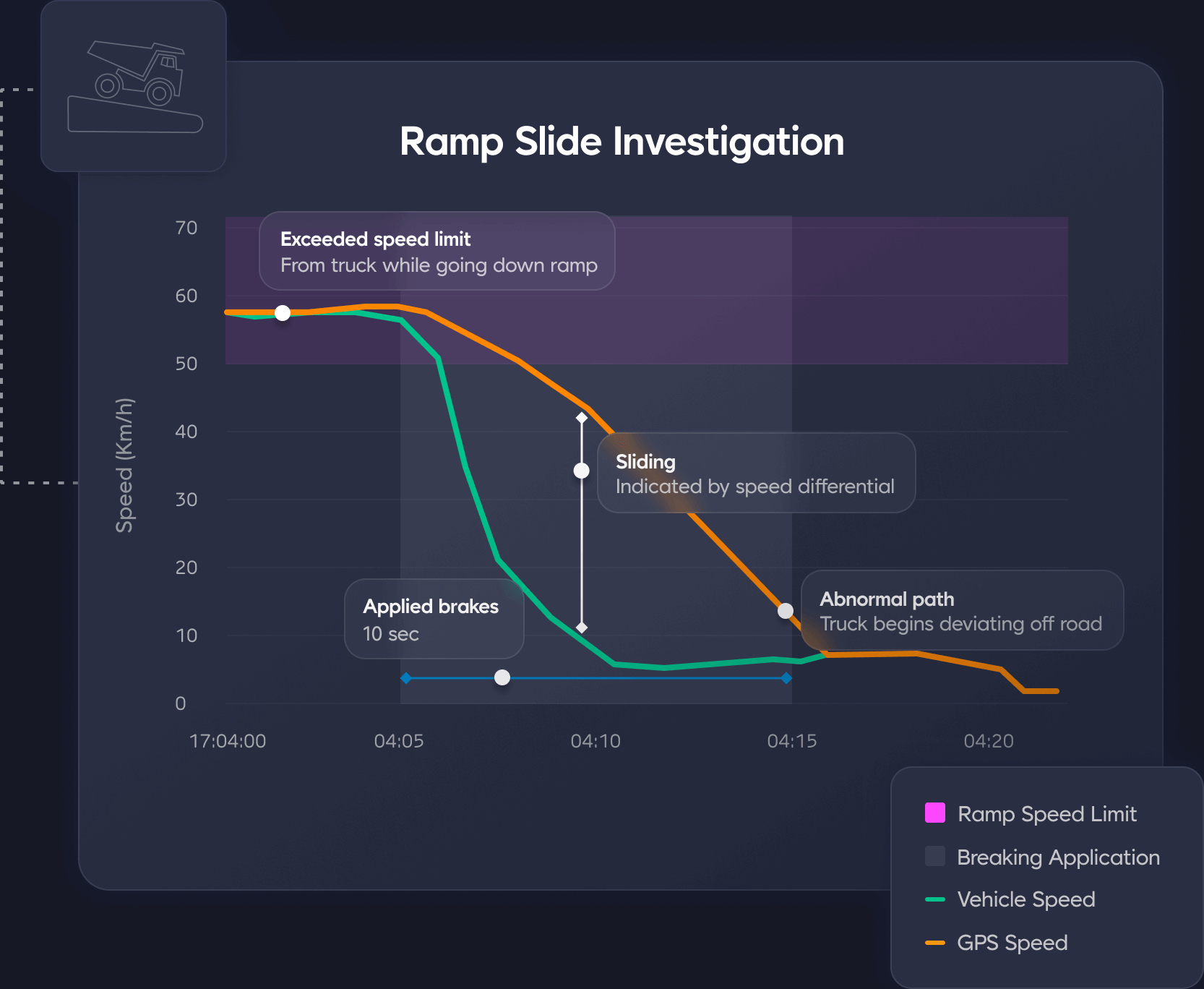

Serious incidents, clear explanations

For serious incidents, our data analysts deliver formal ICAM-style reports to uncover root causes. This independent analysis links each event to clear, practical actions for improving safety.

Haul roads

Good roads, more loads

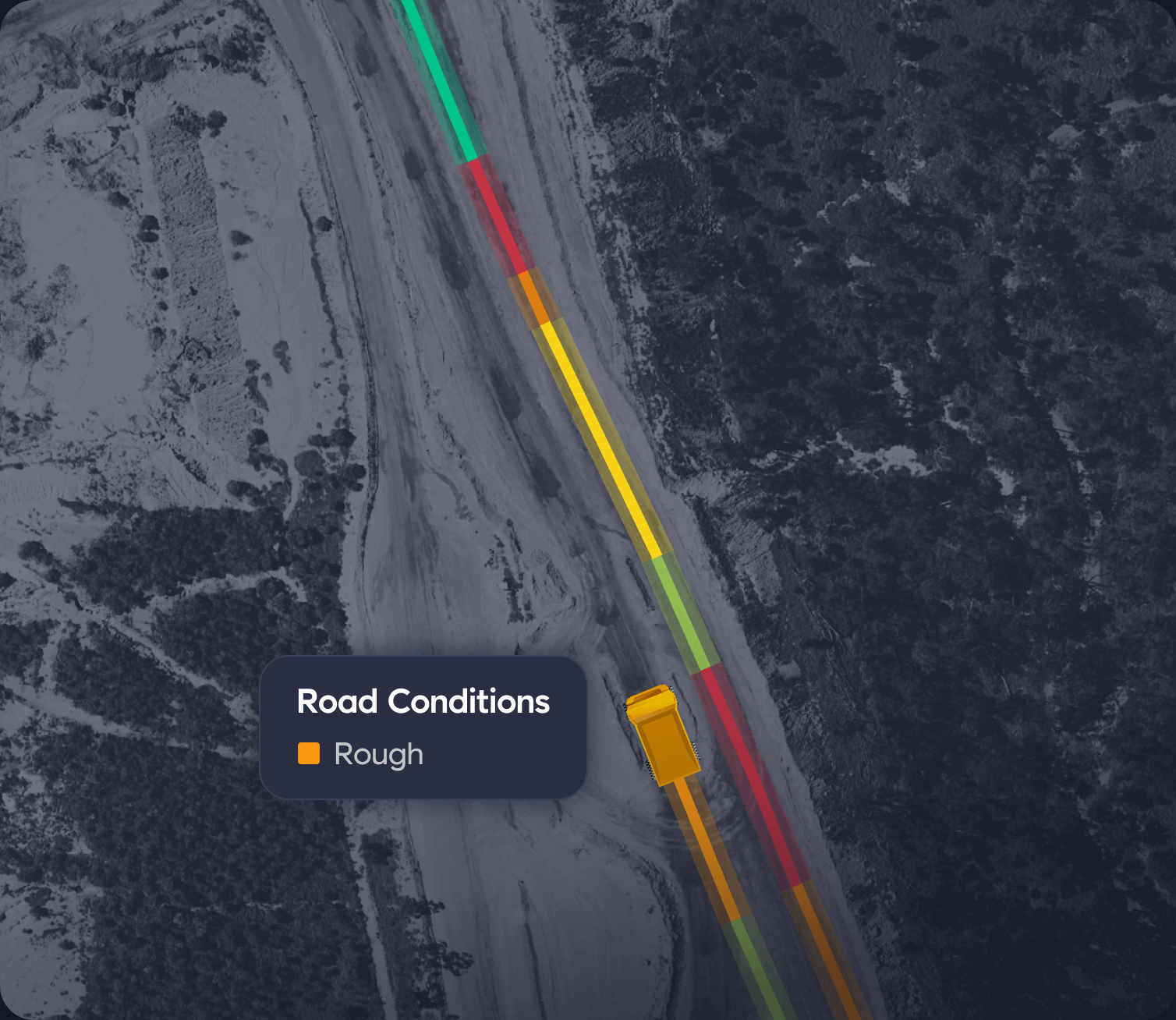

Take the guesswork out of haul road maintenance and refocus your ancillary fleet efforts. MaxMine is the only system to give you a complete picture of haul road condition across your site.

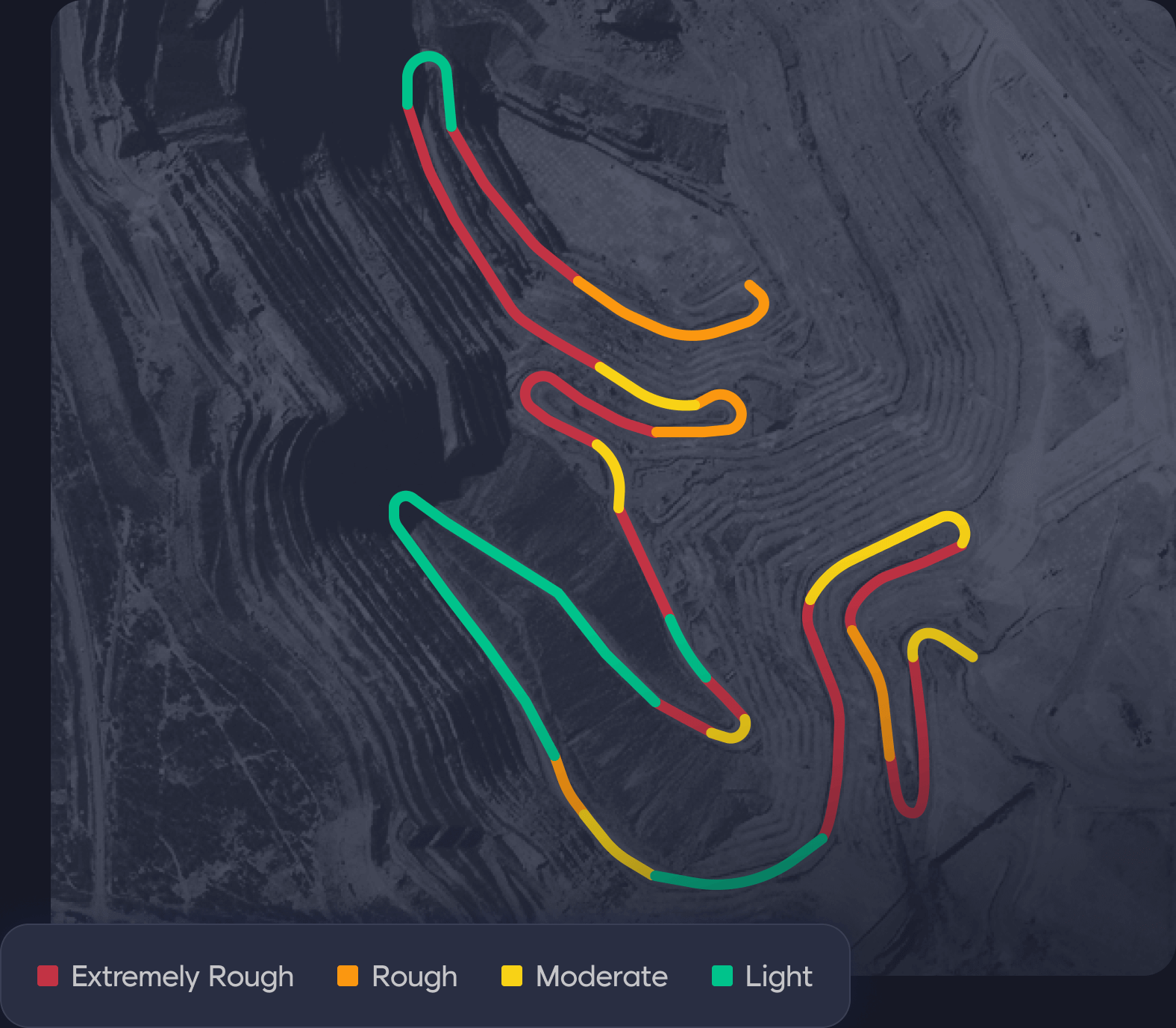

Accurate, independent road condition measurement, without extra sensors

With MaxMine your haul trucks become sophisticated road condition sensors, constantly monitoring and reporting surface quality through advanced strut pressure analysis.

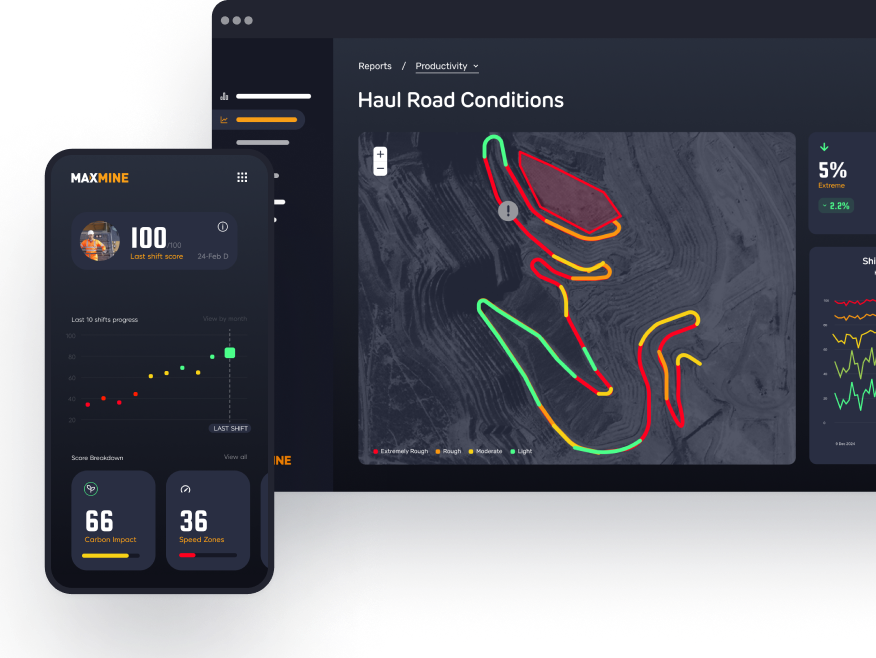

See your haul roads in a new light

Dynamic heat maps on high-resolution satellite imagery show exactly where attention is needed – giving you full visibility across your haul network without driving the pit.

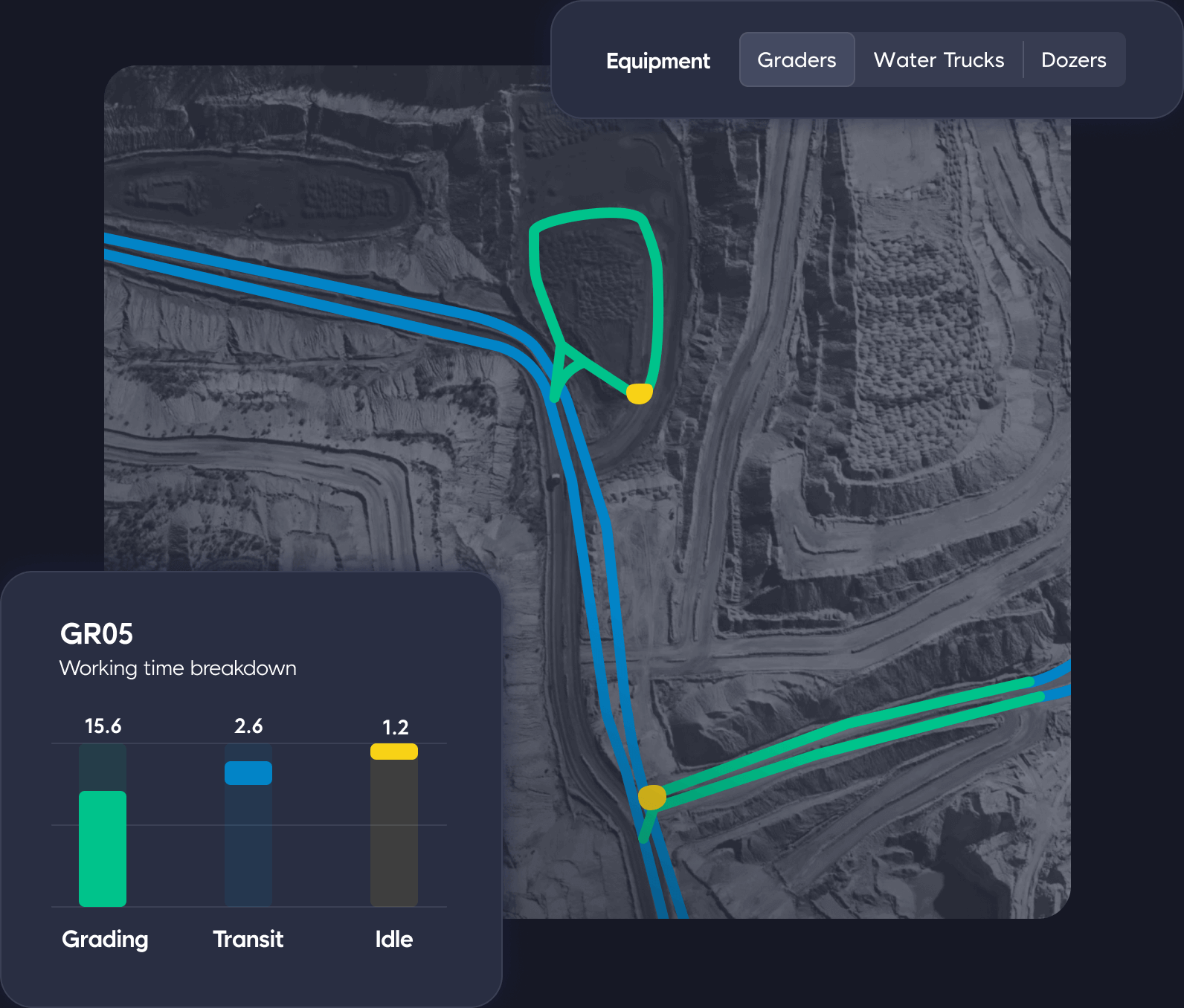

Ancil activity demystified

Stay on top of all productive time with automated activity classification, giving you a clear shift-by-shift view of ancil equipment performance.

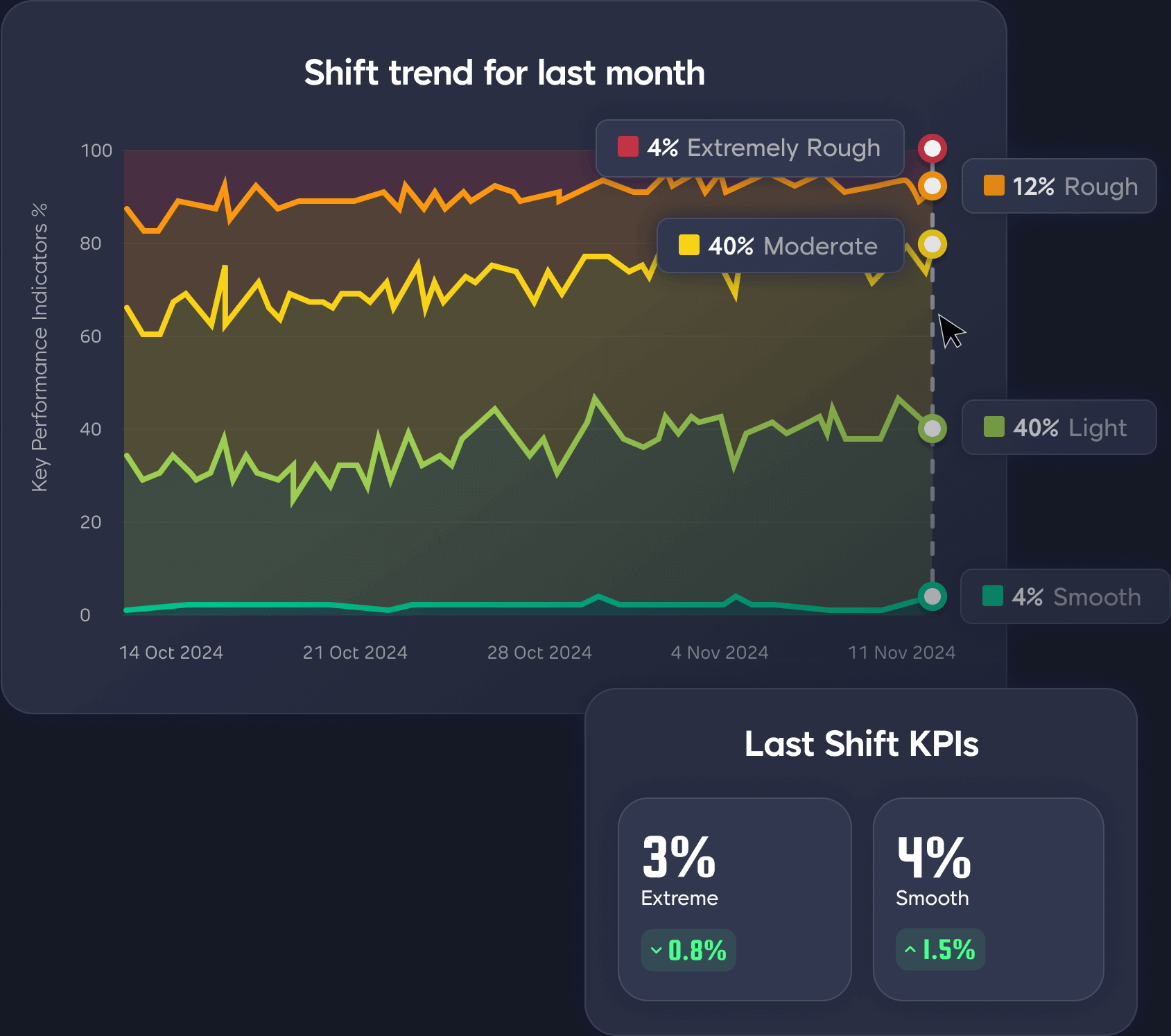

Know where you stand

Know exactly how your haul roads are performing each day, with clear KPIs and trend insights to guide road construction activities.

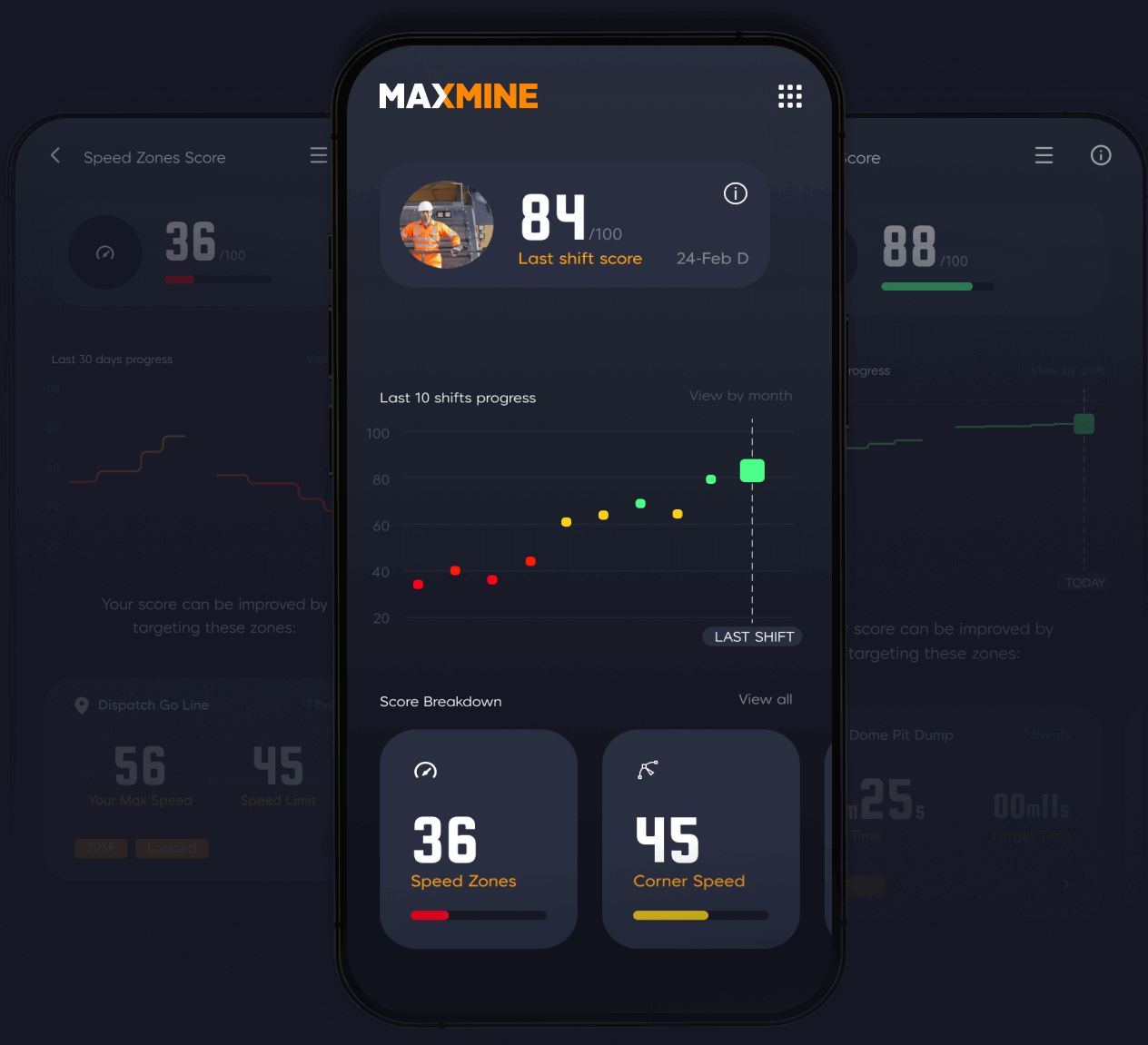

Operator behaviour

Eliminate operator variability. Drive performance at scale.

Automated, data-driven insights operators trust – free from human bias and focused on what’s in their control so that everyone owns their own improvement journey.

Exposing the variability across your operators

Most sites are surprised by how much operator performance varies when MaxMine is first turned on — even with the same training and instructions for everyone.

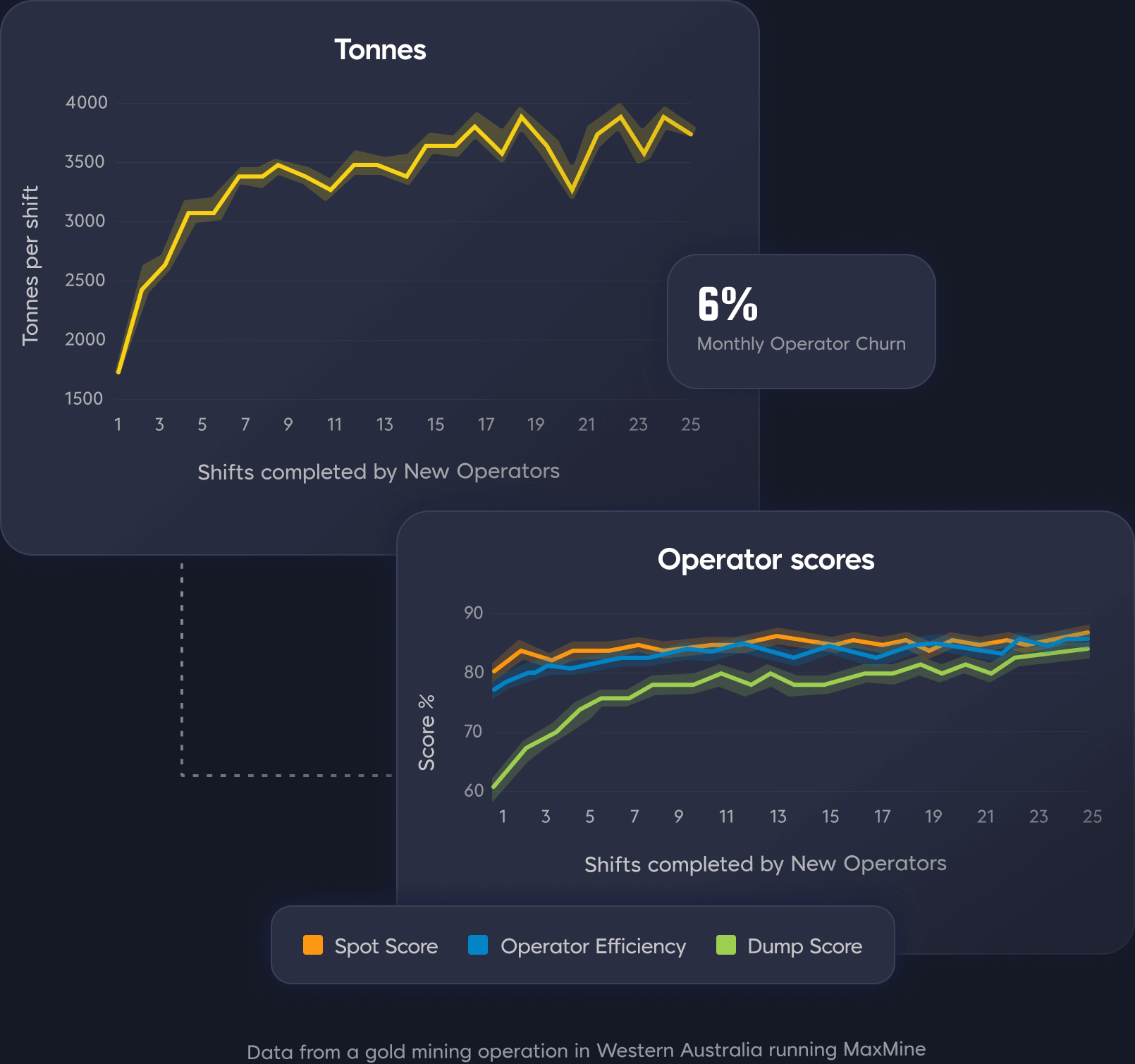

Drive consistency. Unlock productivity

MaxMine levels up operator performance across the board, creating predictable operations and conveyor belt–like consistency that drives increased productivity.

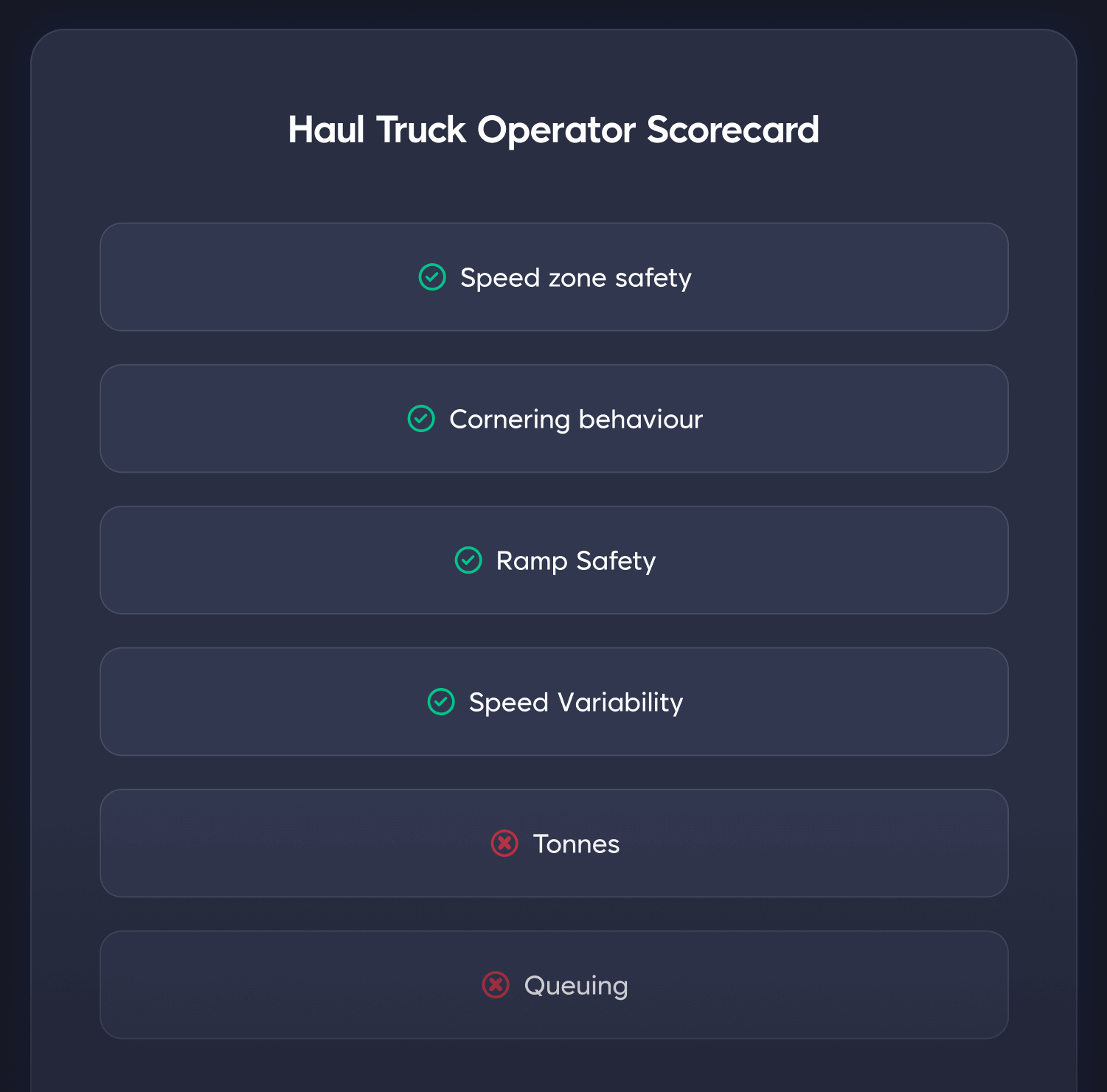

Fair metrics for real performance gains

Operators can’t control everything — so MaxMine zeroes in on what they can. That’s why it earns their trust and drives real change.

Everyone can see how they’re travelling

With personalised shift results and transparent metrics in their pocket, operators know exactly where they stand — and where to improve.

Sustained performance, even with high-turnover

Even with the challenge of workforce turnover, sites with MaxMine continue to see improvements in performance. By fostering a culture of learning and collaboration, new operators quickly adapt and align with seasoned operator’s performance skills, driving consistent results across the team.

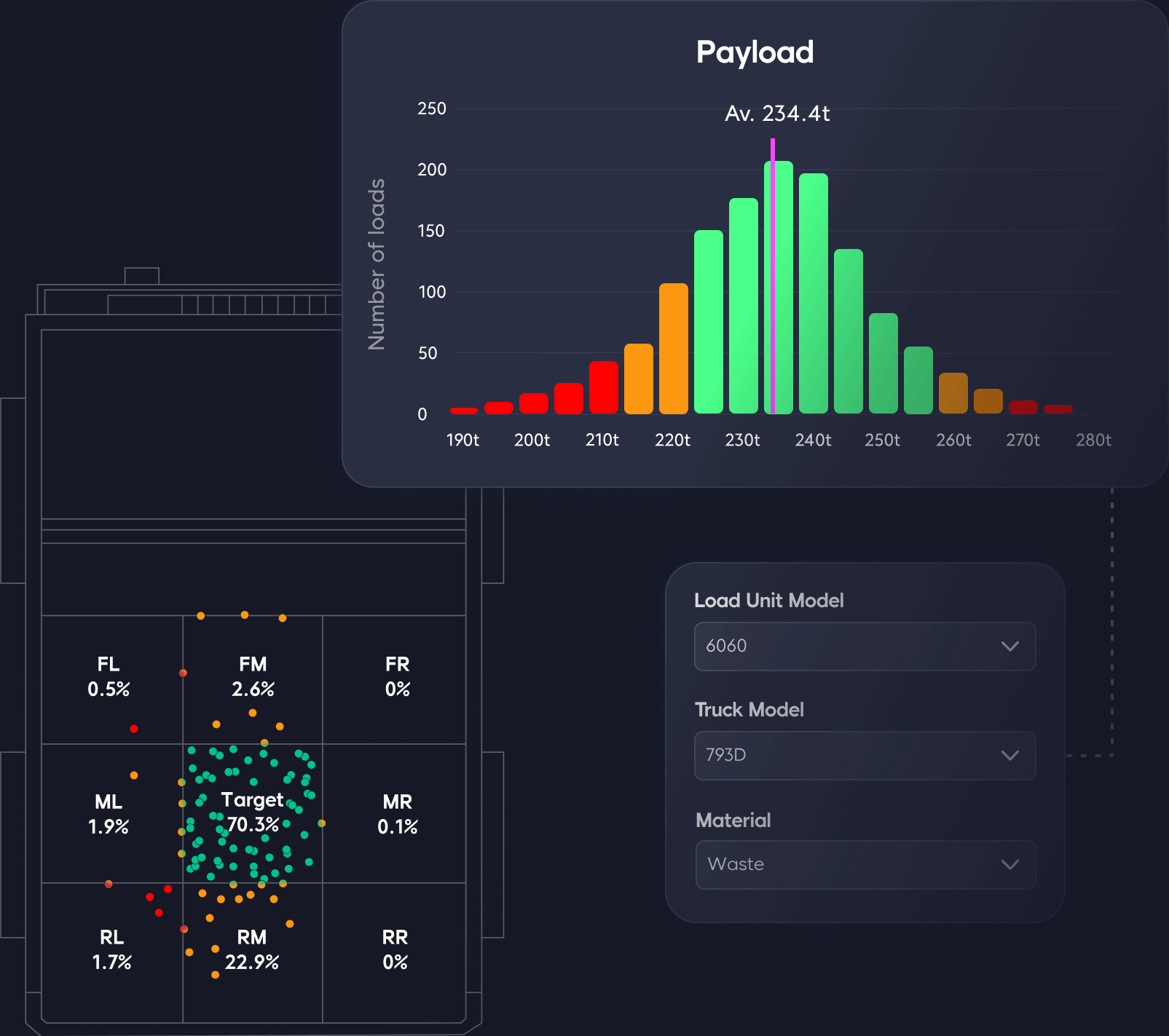

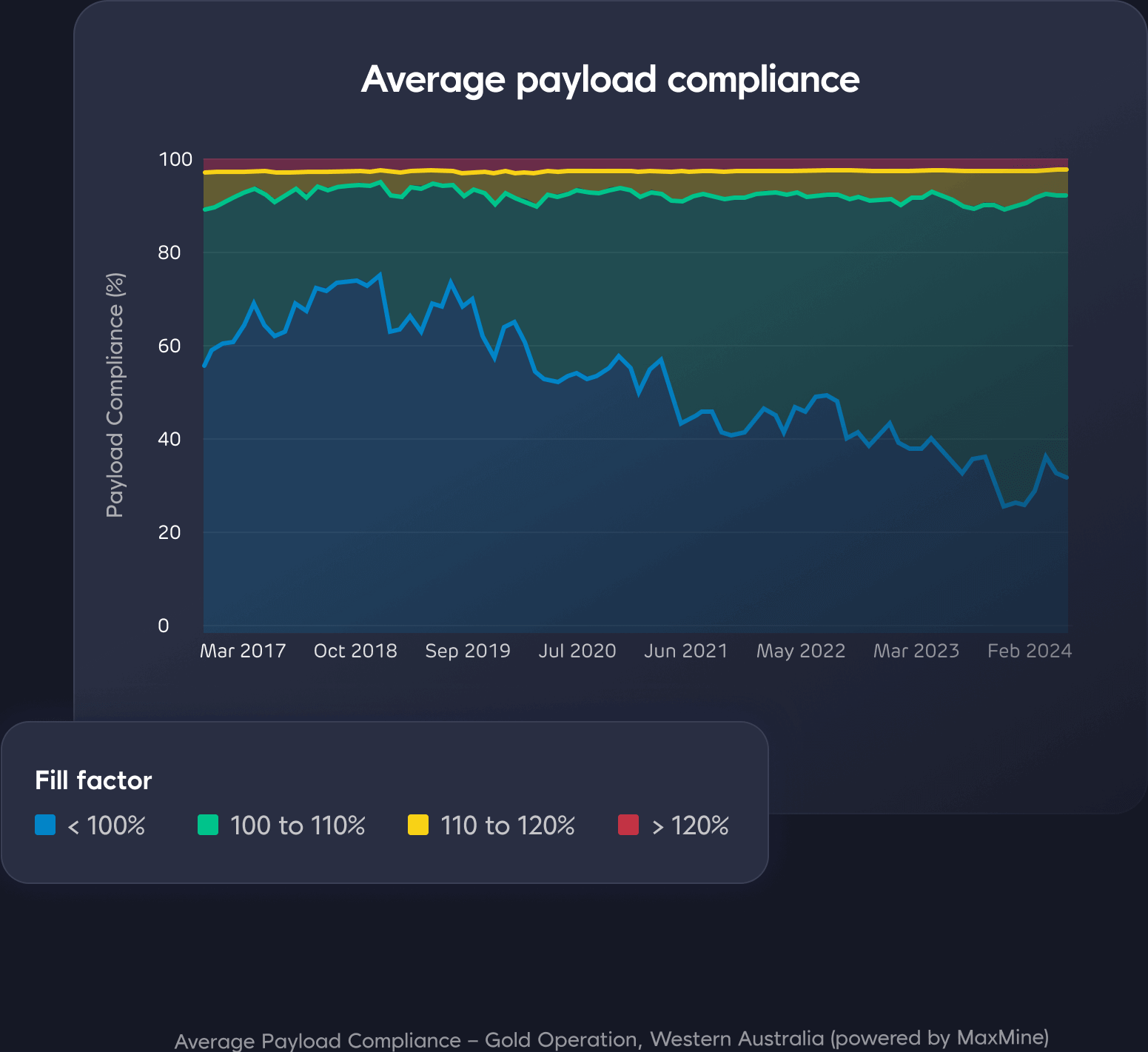

Payload Optimisation

Make sure every tray is full

Payload accuracy, redefined. Our proven algorithm works independently of onboard OEM systems to give you precise metrics for every haul.

No more payload studies or weigh bridges

Unlike OEM systems that rely on a single snapshot per haul, MaxMine continuously analyses hundreds of data points. Our algorithm combines strut pressure and suspension geometry for unmatched precision.

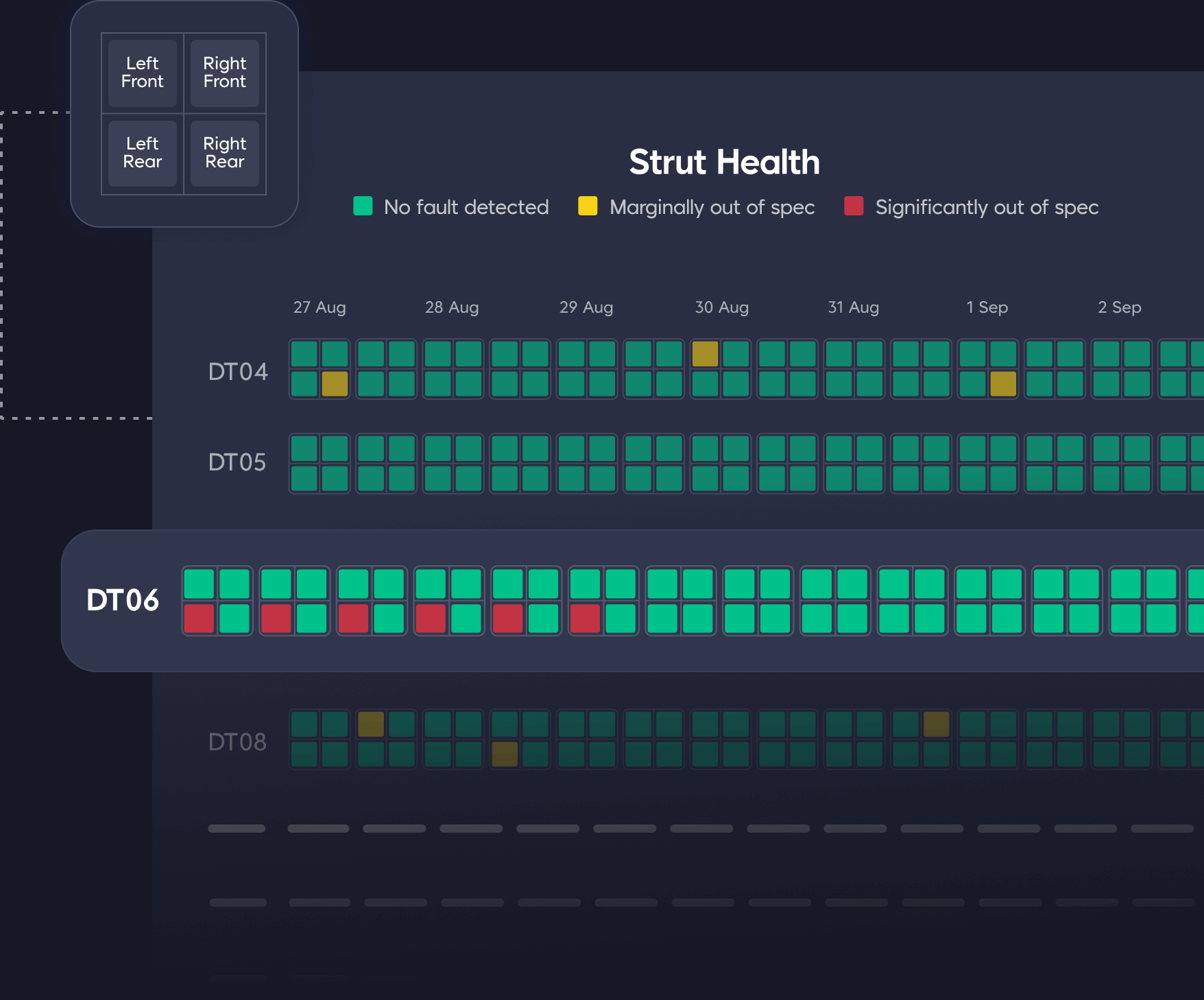

Online strut diagnostics for accurate payloads

Strut problems are identified online, without disrupting production. Detect issues like undercharged or misaligned struts, sensor faults and low pressure during haul transits to enable repairs during scheduled maintenance.

Advanced tools for payload optimisation

See payload by operators and load units to hone in on specific trends and identify opportunities to optimise performance. Set payload targets per equipment, material and tray type for ultra precise loading feedback.

Payload performance shouldn’t break your trucks

Overloads of equipment lead to premature failures. Our payload improvement tools drive loading quality, not just quantity. We bake in the “10-10-20” rule as a common thread so that it’s easy to enforce and correct exceptions.

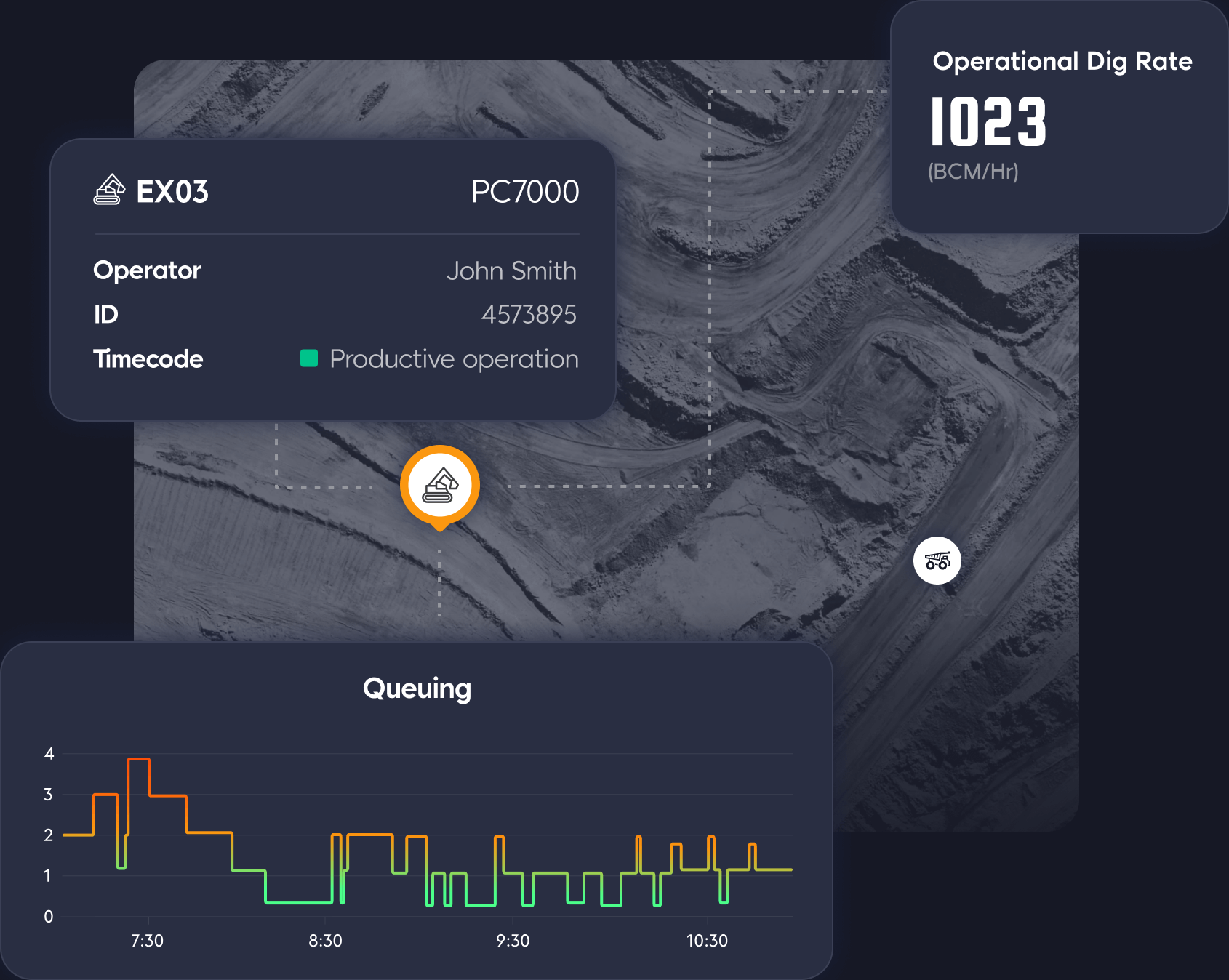

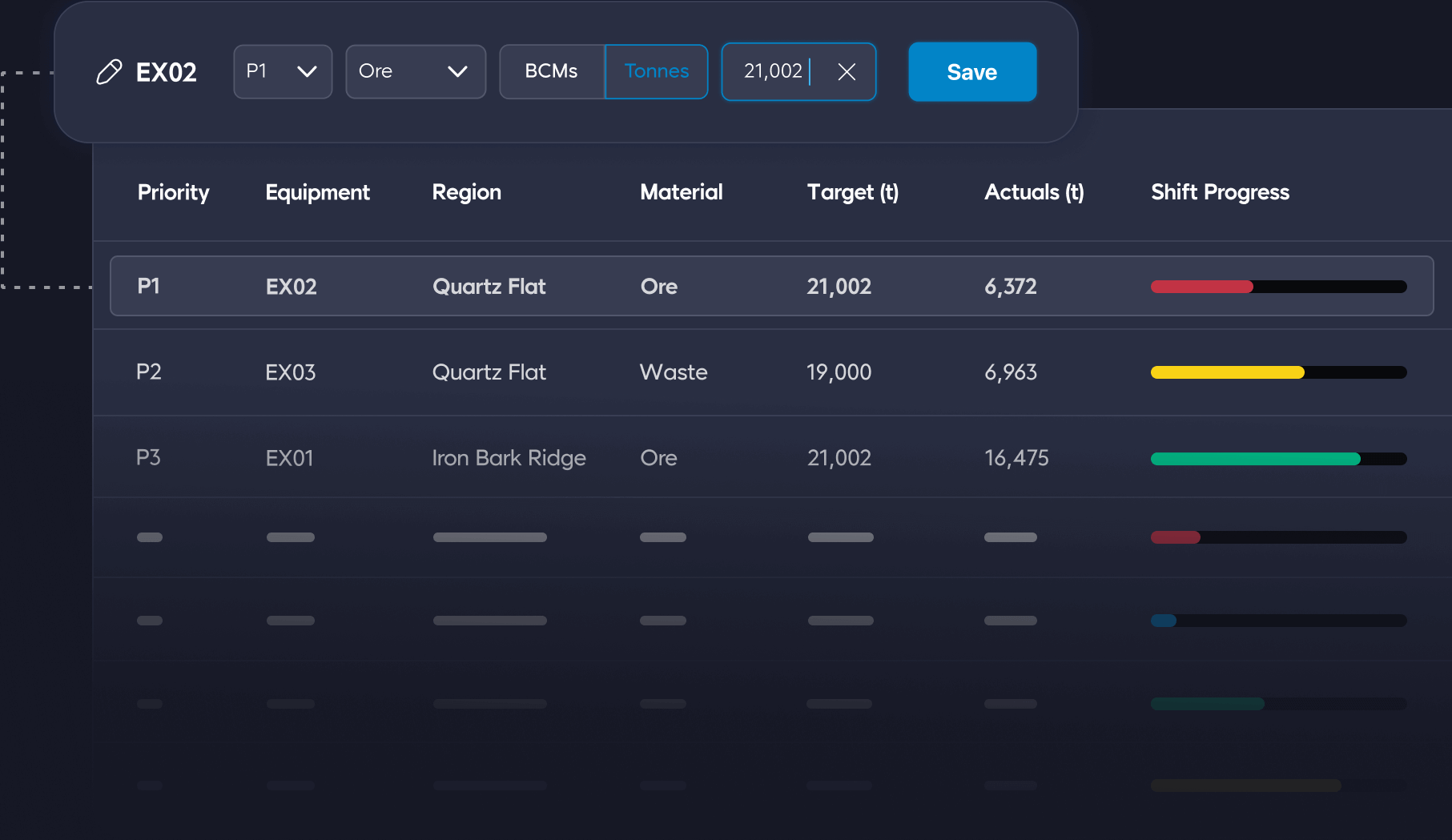

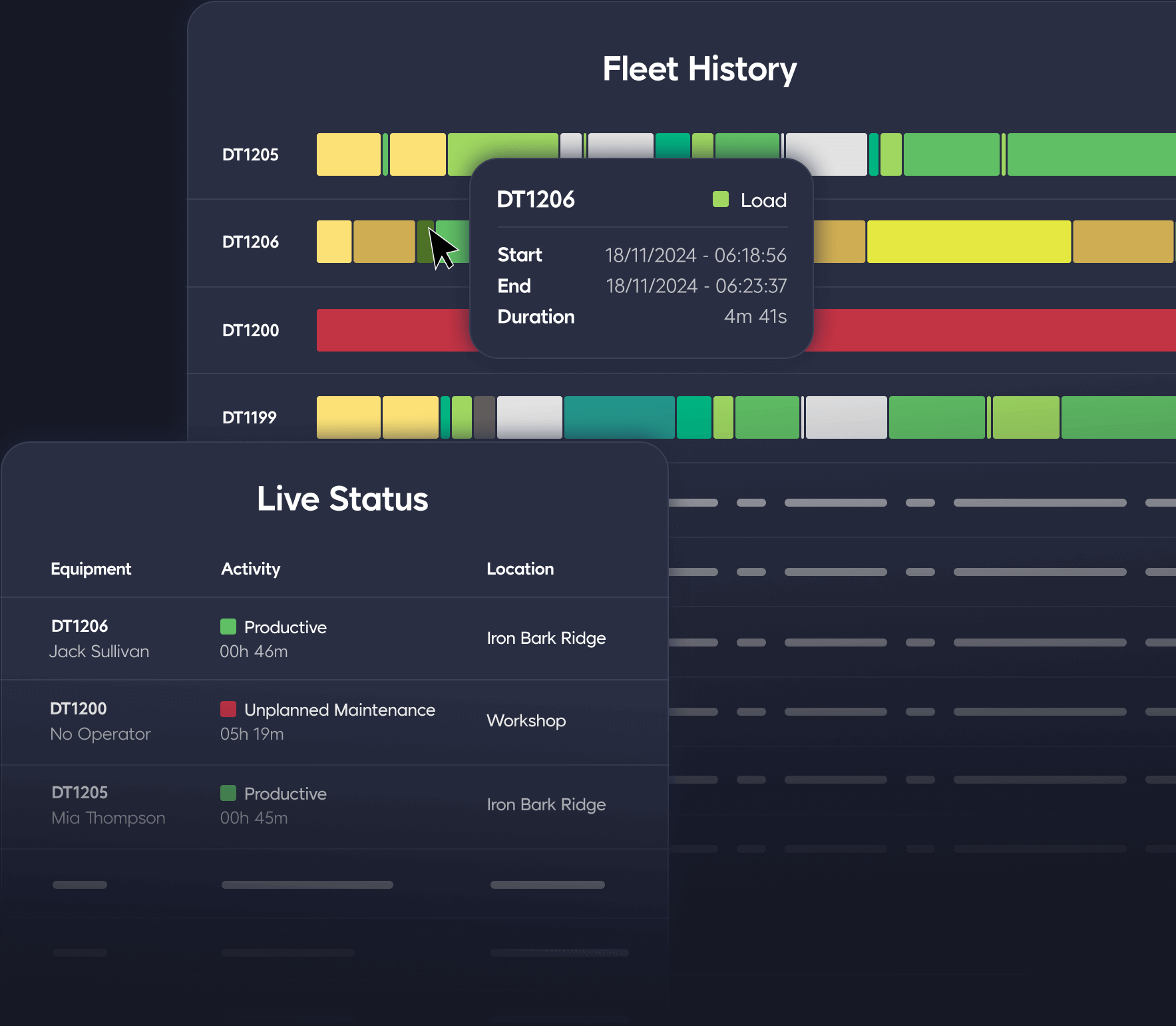

Short Interval Control

Tools to help people make better decisions, faster

Stay in control of execution, meet your production targets and get the whole team working better together.

Live visibility that drives decision making

See what’s happening intra-shift in near real-time with live asset locations and individual circuit performance. Quickly adjust operations to stay on track.

Link targets to production

Set targets for a shift and evaluate production progress relative to plan. View your fleet and hone in on underperformance.

Make every second count

Track every machine’s utilisation down to the second. We combine operator delay capture with machine learning powered auto classification for unmatched time usage accuracy.

Your daily production report, paper free

Walk into your morning production meeting with confidence. Have all the detailed, up-to-date insights on the previous day’s performance across material movements, hours and safety to have the right conversations and drive better decision making.

MaxMine by the numbers

91

equipment models with MaxMine installed

158

incident investigations conducted

400MT+

tracked and optimised annually

10M+

equipment operating hours captured